Maintenance Of Ball Mill

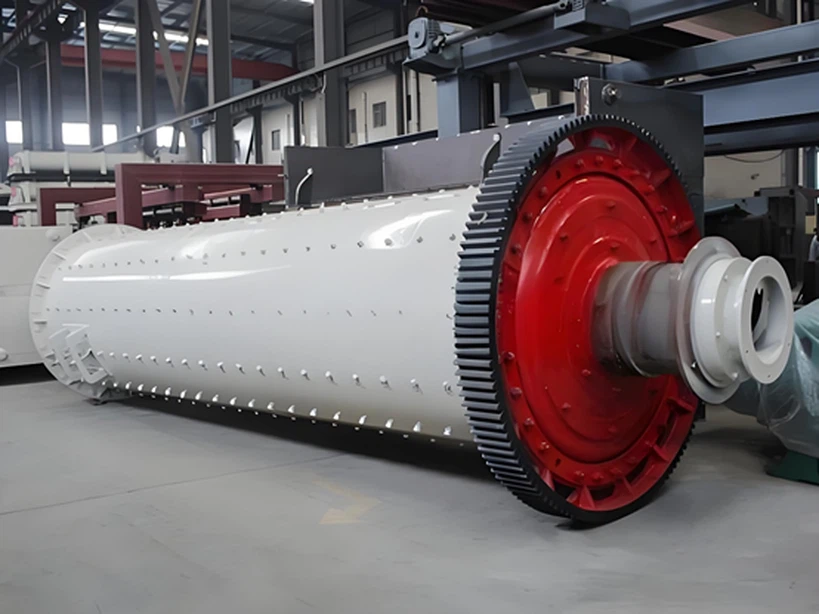

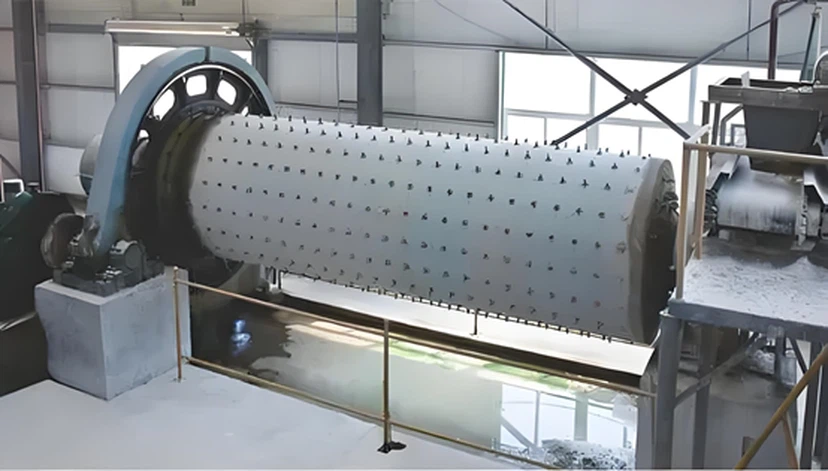

Introduction of Ball Mill

A ball mill is a grinding machine that grinds or mills materials using falling grinding balls. It is a common equipment for grinding materials. When the ball mill machine rotates, the discharged material will be brought to the top and then dropped. The ball mill uses the impact of the falling grinding media to grind and mix the incoming material. In this way, the discharged material is continuously ground.

Classification of Ball Mills

Ball mills can be divided into dry ball mills and wet ball mills according to the grinding method. Dry grinding does not require water, and the materials are usually ground into powder. Wet grinding requires water, and the materials are ground or rounded by the action of grinding media and water.

According to the shape of the body, it can be divided into cylindrical ball mills, conical ball mills, and tube ball mills

Maintenance of Ball Mill

When customers buy mining mill, the manufacturers will give them a brief introduction to the precautions to be taken during use. This is one-sided, and in the actual operation of ball mills, what do we need to pay attention?

Then, We MR technicians will introduce to you one by one the matters that we should abide by during the operation of ball mills.

1. While in operation, pay attention to whether the ball mill machine is leaking, and carefully observe whether the current voltage, material feeding, and water supply are normal. Check the temperature of the motor and main shaft is not greater than 60°С every half hour. Take immediate action if any problems are found.

2. Rotate the equipment for a full circle to check if there are any obstacles in the moving parts or around the equipment and remove them. No one is allowed to stand near the equipment during startup.

3. After the ball mill is running normally, strictly follow the regulations for water supply, feeding material, and adding steel balls. Do not overload the equipment. The idle time should not exceed 15 minutes to avoid damaging the lining plate.

4. Check everything carefully before starting the motor by pressing the start button. Pay attention to the current changes. The mining ball mill may not be started more than twice in a row. The interval between the first and second start should be at least 5 minutes. If the third start is needed, it must be done with the cooperation of an electrician and a maintenance worker after checking the equipment. It is not allowed to start the ball mill machine at the same time as other equipment. It should be started one at a time to avoid power outages.

5. Check all parts of the ball mill machine and electrical equipment before starting, including whether the connecting bolts are loose; whether the lubrication points are normal; whether the transmission device is functioning properly; whether the protective devices are in good condition; and whether the electrical instruments are sensitive and the carbon brushes of the motor are in good contact.

6. Clean the equipment after the equipment is shut down, and practice civilized production.

7. Before shutting down the ball mill for mining, stop feeding the ore first and then stop water supply once the ore in the mill has been processed. Press the parking button and turn off the power switch.

8, In case of unannounced power outage, first pull the disconnect switch, press the stop button, stop feeding ore and water.

9, During operation, pay attention to whether the hollow shaft and oil ring are rotating with oil, and whether the hollow shaft temperature is normal. If you find that the hollow shaft is heating up and approaching burnout, you should immediately take forced cooling measures and do not stop immediately to avoid “bearing lock”. At the same time, pay attention to check the oil volume and temperature of each lubrication part, and refuel regularly.

For ball mills, repair and maintenance are also a routine task. The quality of maintenance work directly affects the operating rate and service life of the ball mill. We MR have more than 50 technicians in our company, who can travel abroad to help our customers install the ball mill machine and offer training classes to local workers. If you have any question about maintenance of ball mill, feel free to contact us immediately!