Argentina: Dolomite Raymond Mill Shipment

MR recently successfully delivered a batch of high-performance Raymond mills to a major mining client in Argentina for their core dolomite processing project. Throughout the project lifecycle, we provided comprehensive VIP service: from initial technical solution consultation and equipment selection advice to subsequent installation and commissioning guidance, all supported by a professional team familiar with mining processing techniques.

Notably, our sales engineers and installation technicians are fluent in Spanish, enabling precise technical communication in the client’s native language. This not only ensures accurate project execution but also provides peace of mind during the large-scale equipment procurement process. This localized, professional service is MR’s key advantage in the American market.

Details of this dolomite Raymond mill production line are as follows:

Raw Material: Dolomite

Feed Size: Under 200mm

Discharge Size: 325 Mesh

Passing Rate: 99%

What is Dolomite?

Dolomite (CaMg(CO₃)₂) is a sedimentary rock composed of calcium-magnesium carbonate minerals. It typically appears white, off-white, or light yellow. It has a high hardness (3.5-4 on the Mohs scale) and good thermal and chemical stability. It is widely distributed worldwide. Dolomite can be ground in a Raymond mill to produce a powder with a mesh size of 80-400 or even finer to meet various industrial needs.

In the building materials industry, it is an important raw material for the production of glass, ceramics, and refractories, improving the products’ high-temperature resistance.

In the metallurgical industry, it effectively removes impurities as a flux in steelmaking.

In agriculture, dolomite powder regulates soil pH and provides magnesium. Environmentally, it is used in wastewater treatment and flue gas desulfurization.

Due to its abundant resources and low cost, dolomite powder has high economic value in industrial applications. The efficient grinding capacity of the Raymond mill makes it a key piece of equipment for dolomite processing, helping customers achieve high-value-added resource utilization.

MGW Raymond Mill Advantages

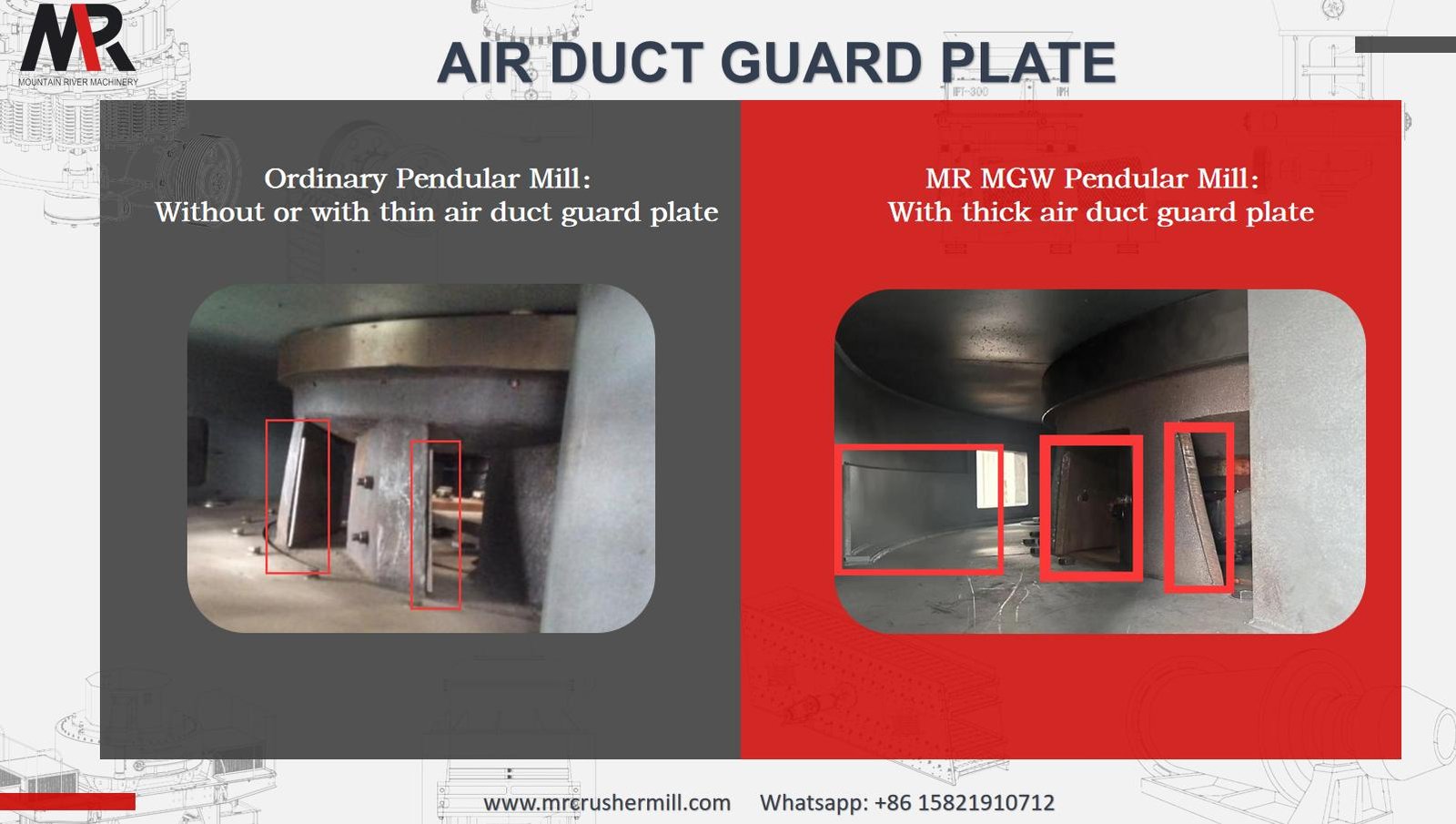

1. The inner surface of the internal door panel of the MGW series Raymond mill is aligned with the inner surface of the air inlet volute, effectively preventing eddy currents. The plate is made of imported wear-resistant steel, which offers exceptional mechanical strength. Its mechanical properties are three to five times greater than those of ordinary low-alloy steel, significantly improving the wear resistance of the housing and thereby extending the machine’s service life.

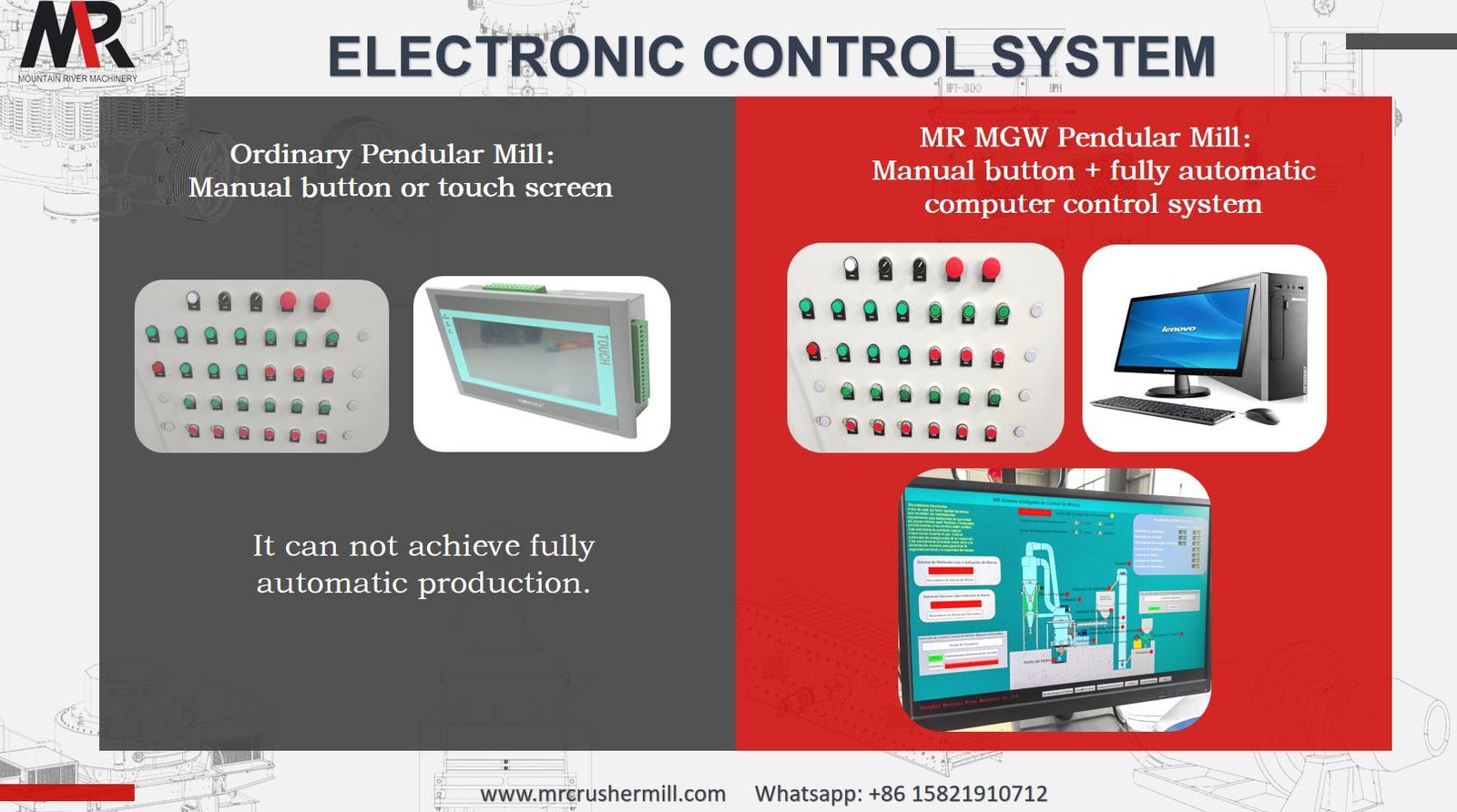

2. The use of computer integrated control equipment is easier to operate (one-button start and stop), reducing the labor intensity of workers; at the same time, it can ensure the uniform feeding of raw materials, avoid and reduce the collision between the grinding roller and the grinding ring, and extend the service life of the machine; in addition, when a computer control system fails, the computer will automatically alarm and shut down, reducing damage to the machine and troubleshooting time; computer control can maximize production, significantly improve efficiency, fully guarantee product quality, and bring substantial profits to the company.

MGW Raymond Mill Maintenance

- When a new machine is put into operation, the bolts connecting all components should be regularly checked for looseness, with particular attention paid to checking the bolts connecting the main unit and the grinding roller assembly.

- The mill should be managed by a dedicated person during operation, and operators should undergo training to ensure they understand the mill’s principles and performance and are familiar with the operating procedures.

- To ensure the proper operation of the mill, a “Safety Operating Procedure for Maintenance and Repair” should be established to ensure the mill’s long-term operation. Necessary maintenance tools, lubricants, and accessories should also be available.

- The mill should be inspected and serviced after a certain period of use. Vulnerable grinding rollers, grinding rings, and scrapers should be repaired or replaced. When replacing grinding rollers, all other rollers in the mill must be replaced simultaneously to ensure the balance of the main unit.