Brazil: Basalt Jaw Crusher Helps Client’s Aggregate Production Line Run Stably For Five Years

Project Introduction

In 2020, client A’s mining crushing production line encountered serious challenges. The used metso jaw crusher was aging and had high maintenance costs, which led to frequent shutdowns of the production line, seriously affecting production efficiency.

Therefore, after inspection and analysis by our engineers, they chose to purchase a new jaw crusher machine from MR and started using it with the help of our engineers.

Raw material: Basalt

Feed: below 600mm

Discharge: 0-3mm, 3-5mm, 5-12mm, 12-19mm

Output: 120tph

Project Process

The Metso c160 jaw crusher that the client initially used was a used jaw crusher, without any after sales service. Due to many hidden dangers, the client originally planned to improve the performance of the equipment by modifying the jaw rock crusher.

When the production line was modified, MR technical engineer went to the client’s site for inspection. During the on-site understanding, he found that the jaw stone crusher of client A had some inevitable problems:

Poor bearing sealing: dust easily enters the bearing seat, resulting in frequent bearing damage and a surge in maintenance costs.

Improper modification affects production: In order to reduce the speed, the client reduced the size of the motor wheel, resulting in a significant drop in the performance of the primary jaw crusher.

Excessive maintenance costs: The cost of replacing the movable jaw assembly and the bearing seat has exceeded the cost of purchasing a new jaw crusher equipment, which is not economically cost-effective.

Jaw Crusher Production Line Solution

The inherent defects of used equipment make the maintenance cost far higher than expected. MR provides a complete solution for the client’s problem:

Replace a new jaw crusher: Use MR PE750×1060 universal jaw crusher to ensure stable equipment performance and avoid potential problems of used equipment.

Optimize bearing seal design: Use high-precision sealing structure to prevent dust from entering the bearing seat and extend the service life of the bearing.

Restore reasonable speed: Match the motor wheel according to the standard configuration to ensure that the pe jaw crusher runs at the optimal speed and stabilize the production capacity at 150tph.

Working Principle

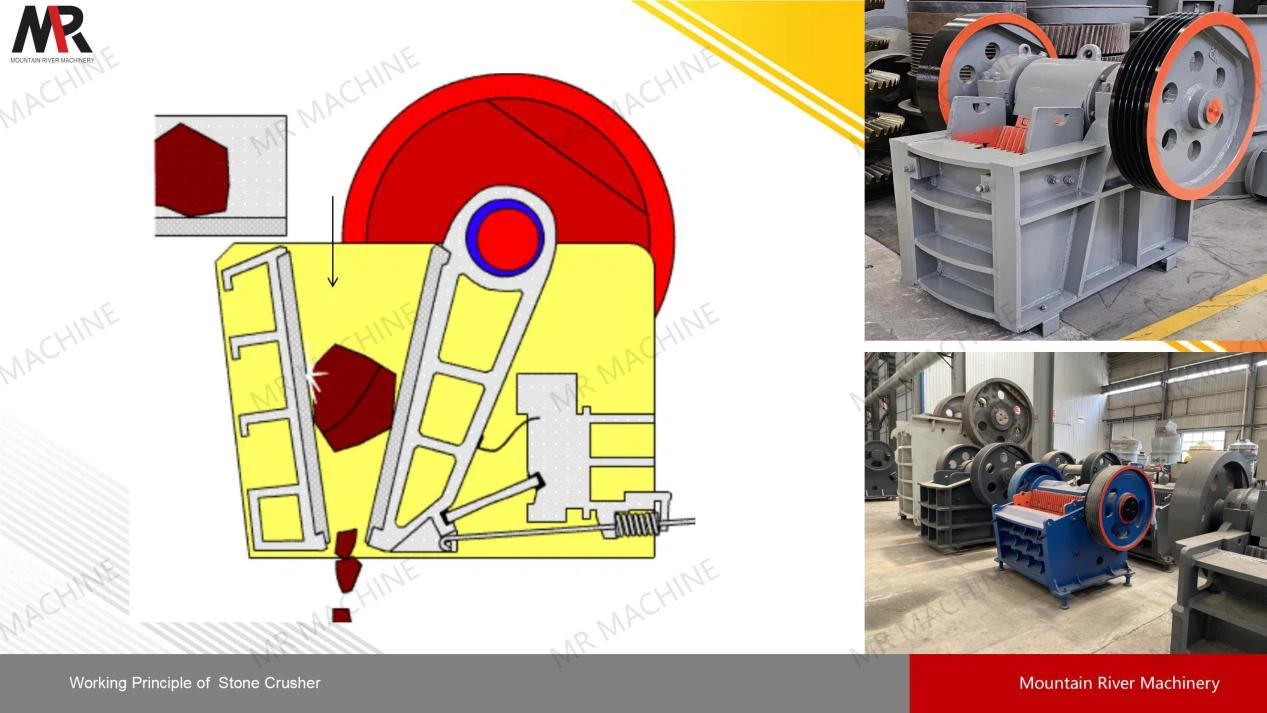

Motor and transmission: The motor drives the belt and sheave, which is connected to the eccentric shaft for jaw crusher. This shaft is essential for the movement of the movable jaw.

Eccentric movement: The eccentric shaft moves the movable jaw up and down, alternating between two positions: one in which the movable jaw is close to the fixed jaw (to crush the material) and the other in which the movable jaw is away from the fixed jaw (to allow the crushed material to leave).

Crushing: As the movable jaw rises, it approaches the fixed jaw and the material caught between the movable jaws is compressed and thus crushed. When the movable jaw descends, the crushed material is discharged through the discharge port.

Crushing chamber: The cavity between the two jaws, together with the side plates, forms the crushing area where the material size reduction process occurs.

This type of mining jaw crusher is well suited for crushing minerals and other hard materials due to its robustness and ability to accommodate different material sizes.

Basalt Jaw Crusher Project Summary

This case fully proves that choosing high-quality stone jaw crusher machine is crucial to the long-term stable operation of the production line. The client originally suffered high maintenance costs due to frequent failures of used equipment.

After replacing the MR chinese jaw crusher, not only the output was stable, but also the maintenance cost was greatly reduced. The five years of trouble-free operation from 2000 to 2005 greatly increased the client’s trust in the MR brand. For key equipment, choosing reliable new equipment is far more economical and efficient than barely repairing used equipment.