Buy Raymond Grinder Must Read: The Influence of Inner Diameter

Introduction

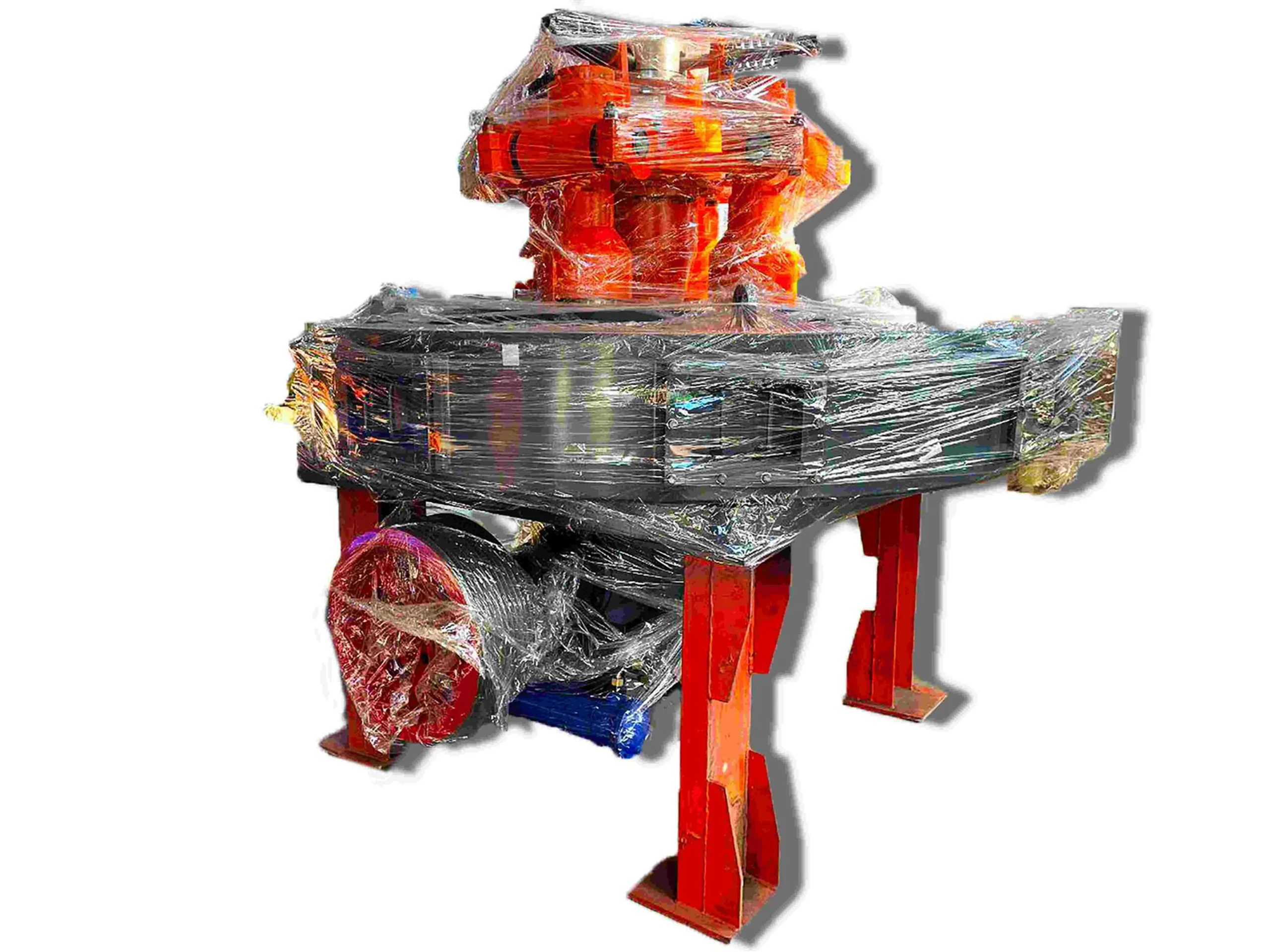

As an important equipment in the field of industrial grinding, the structural design of Raymond mill directly affects the grinding efficiency and quality. A complete Raymond mill is mainly composed of the following core components:

Main mill: including core grinding components such as grinding roller, grinding ring, scraper

Classifier: responsible for controlling the fineness of finished powder

Blower: provides necessary airflow to transport powder

Cyclone collector: completes the separation and collection of finished powder

Pipeline system: connects various components to form a complete airflow cycle

Motor system: provides power for the entire equipment

Among these structures, the grinding area formed by the grinding roller and grinding ring is particularly critical, and one of the core accessory parameters of this area is the inner diameter size of the Raymond mill.

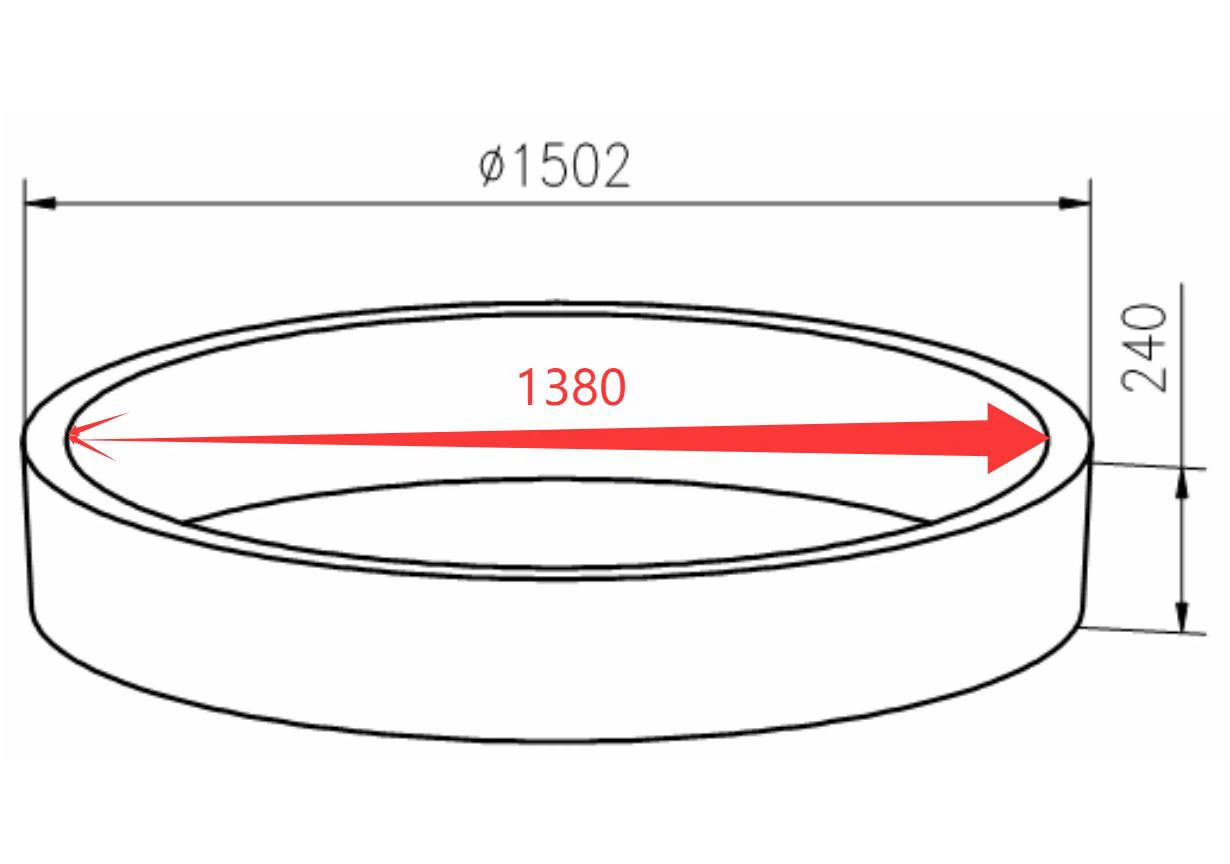

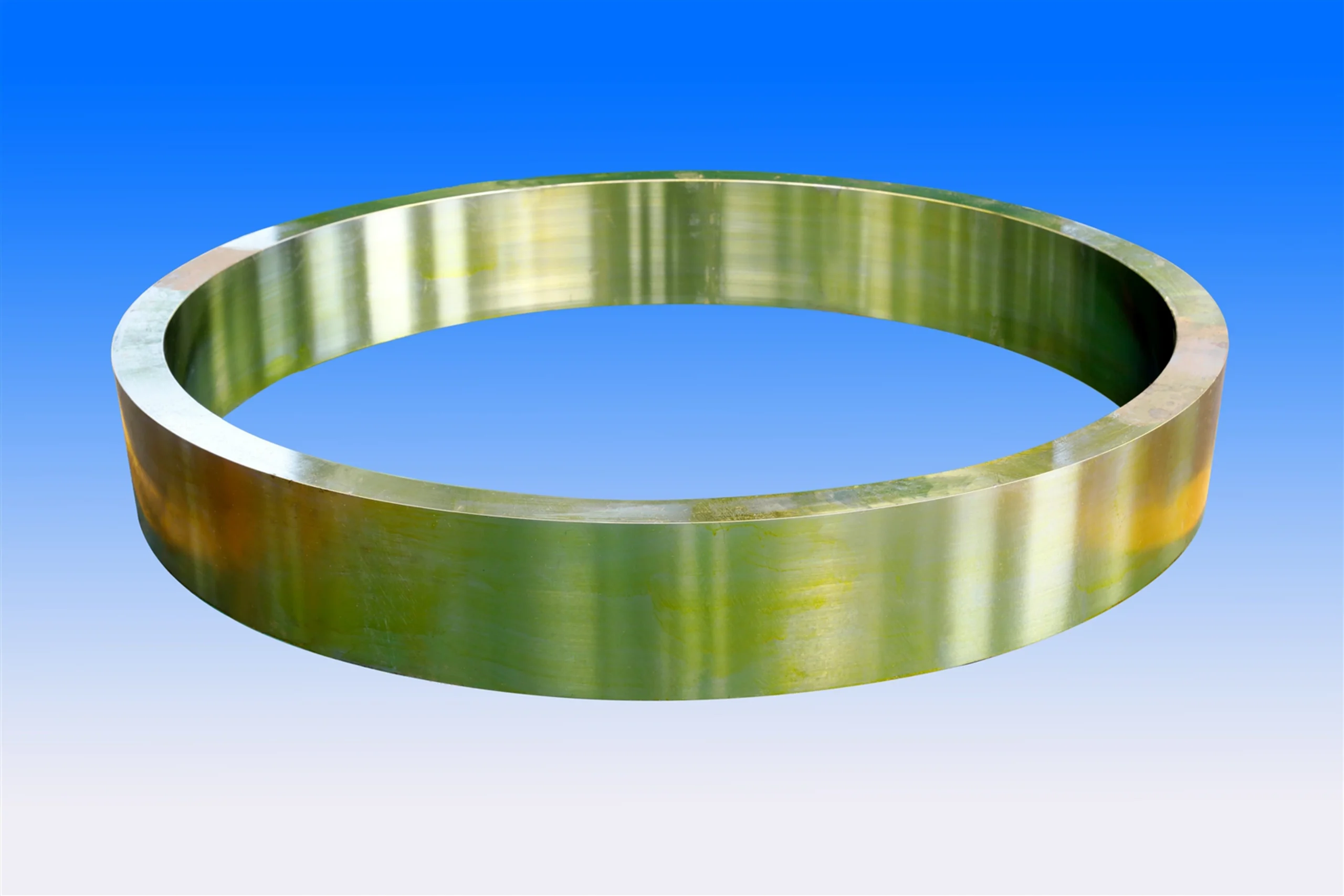

Inner Diameter of Raymond Mill

The inner diameter of the Raymond mill refers to the inner diameter of the grinding ring, the diameter length of the inner ring of the grinding ring. This parameter directly determines the volume of the grinding area, and the naming of each Raymond mill model is determined by the size of the inner diameter. The inner diameters of different models of Raymond mills are significantly different.

It is worth noting that most suppliers directly use the inner diameter of the grinding ring as the basis for model naming, which means that the inner diameter size is positively correlated with the processing capacity of the equipment. However, in actual procurement, some customers or suppliers, due to lack of professional knowledge, mistakenly use the outer diameter of the grinding ring as the main criterion for judging the size and production capacity of the main machine body, resulting in the purchase of a small-sized Raymond mill, and the actual production capacity is lower than the production demand.

Why is the Inside Diameter so Important?

Determine production capacity: The larger the inner diameter, the larger the volume of the grinding area, the more material can be processed per unit time, and the production efficiency is naturally higher. For example: the capacity of a Raymond mill with an inner diameter of 1000mm is usually 30%-50% higher than that of an 800mm mill.

If a customer needs a production of 5 tons per hour, but mistakenly selects a model with an insufficient inner diameter, the actual capacity may be only 3-4 tons, which will seriously affect the production plan.

Determine the equipment footprint: The size of the inner diameter directly affects the size of the main machine, and then it is related to the floor space of the entire equipment, which is of great significance to the plant space planning.

Common misunderstandings when purchasing:

① Mistakenly believe that “machines with large appearance must have high capacity”

Some equipment may appear large due to structural design (such as heightened brackets or wide body shells), but the actual grinding inner diameter has not increased.

② Mistakenly believe that “high price means high configuration”

The high price may be due to certain factors such as additional functions (such as intelligent control systems), but if the inner diameter does not match the demand, the basic capacity cannot be increased.

How to Choose the Right Inner Diameter?

1. Clearly define production requirements

Expected output: Calculate the required inner diameter range based on the amount of finished powder required per hour or day. Generally, the output is proportional to the cube of the inner diameter.

Material characteristics: Materials with high hardness and density often require equipment with a larger inner diameter to ensure sufficient grinding force.

2.Check the model code:

For example, the “138” in our company’s MGW138 usually refers to the inner diameter of the grinding ring 1380mm. The meaning of the model needs to be confirmed with the supplier.

3. Long-term development considerations

If the budget and site allow, an inner diameter model slightly larger than the current demand can reserve space for future capacity increases and avoid the passive situation of equipment upgrades in the short term.